I’m sure that when you read the title Production Division Gun Build, you had a few choice thoughts run through your mind. I know, the prospect of a customized gun for an out of the box division is absurd. With that said, I’m not sure I know how else to describe what I’m in the process of doing.

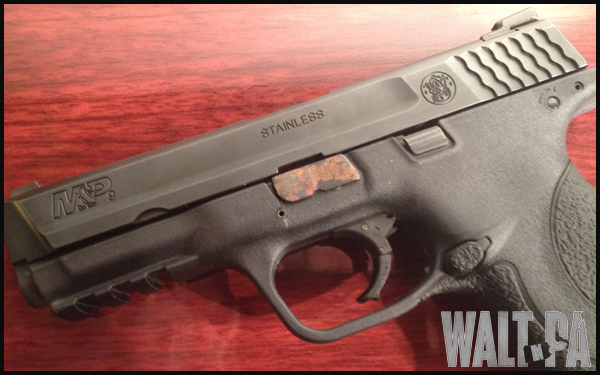

My first range gun, a Smith & Wesson M&P, has had its fair share of problems over the years. We’ve battled rust on the slide, rust on the magazines, dots falling out of the sights, and the locking block coil pin removing itself from the frame.

Despite the problems with my M&P, I still have a fondness for the gun. I no longer shoot it in competition but no longer want it to be the gun that is hidden away in the safe. To breath a little life into this gun, I’ve taken a few steps to freshen it up and make it more appealing to shoot.

Repairs

My first experience with Smith & Wesson Customer Service came in December of 2011. I returned from a range trip where the locking block coil pin began removing itself from the frame. This problem, coupled with surface rust marred slide, was too much. I no longer wished to deal with the problems since this gun shared a safe with several others, none of which had a spec of rust on them.

I felt as though the rust was a quality issue and not my problem to deal with. Smith & Wesson Customer Service agreed and I had a pre-paid shipping label in my possession within in a few days. Between four and six weeks later my M&P was returned from the factory with all problems resolved.

Thrilled with my like-new M&P, I began hitting the range once again. A couple of months later I found that the finish on my magazines was wearing thin. I wasn’t terribly surprised, it was bound to happen with heavier than average use plus dry-fire practice / reload practice. Despite keeping them lightly oiled and cleaned between uses, surface rust plagued me again.

Around the same time the magazines began rusting, two out of the three dots on my sights fell out. Frustrated, I stuck the M&P in my safe and purchased a Glock 17 for USPSA Production Division. The M&P sat unused for several months until one day I pulled it out for a little range time. Things had gone from bad to worse. In addition to four rusted magazines, I now had rust on my rear sight, rear slide serrations, and takedown lever.

With the gun already having been repaired once by Smith & Wesson, I had my doubts that they would fix it again. To my surprise, the phone call to customer service couldn’t have gone any smoother. Within a few days I had a pre-paid shipping label and my gun was off to Smith & Wesson once again.

Fed-Ex picked up my M&P on November 1st and returned it to me on November 14th. The turnaround time was amazing and the returned gun was even better than I expected. All of my issues were resolved and the finish on both the magazines and the gun looked, and felt, better than ever before.

My desire to shoot the gun more often was reinvigorated and I began to think about ways to make it more appealing in competition.

New Sights

When it comes to pistols, the vast majority of my experience has been with 3 Dot Sights. I was comfortable with the system and had no desire to change. Even when the dots fell out of my M&P Sights, I raided my wife’s nail polish and repainted them myself.

When I made the switch to Glock, I quickly learned that I wanted no part of the system they used. The giant white ‘U’ on the rear sight was very distracting. I found that I struggled to focus on the front sight and made the decision to switch them out to aftermarket sights.

I came across Warren Tactical Sights with a plain black rear and a fiber optic front. I was skeptical of the plain black rear and wasn’t sure how I would like it. I set my concerns aside and placed my order. The first time I pressed the gun out in competition, I was in love. To this day I consider those sights the best money I’ve ever spent on a firearm accessory.

With a fondness for Warren Tactical Sights, my plan was to dump the factory M&P Sights and use the same system that was now on both of my Glock pistols. That all changed when my M&P was returned from Smith & Wesson. For some reason, and I’m not complaining in the slightest bit, my stock sights were upgraded to night sights.

While these new sights aren’t what I had in mind, they do open up a couple of options I hadn’t considered. Aside from the gun looking like a good nightstand option, IDPA Low Light matches are now calling my name. I’ve been testing the gun in various lighting conditions and in all of them the sights have been easy to pick up. As a result, they are going to save me money and remain on the gun.

Trigger Upgrades

If you were to perform a Google search looking for issues with the M&P Platform, the biggest issue, by far, would be complaints of the trigger. Most notably the trigger reset. Perhaps it is my limited experience, but I’ve never found the trigger on my M&P bad enough to abandon the platform or try to steer others away from buying one.

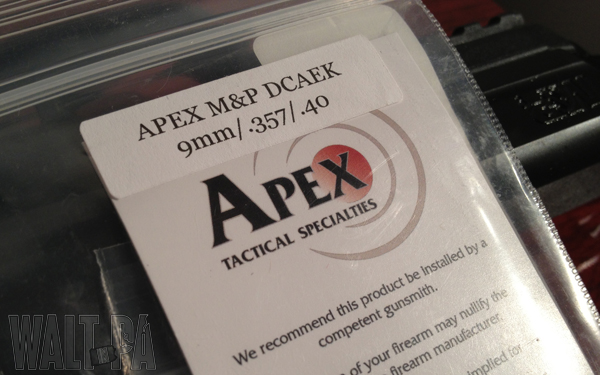

While I’ve never found the M&P trigger to be horrible, I think there is room for improvement. For some time now I’ve been considering picking up an Apex Tactical Trigger Kit. It wasn’t until When The Balloon Goes Up put on a Black Friday Sale that I bit the bullet. With the kits coming in at 20% off and my interest in the M&P platform reinvigorated, I couldn’t pass up the opportunity for an early Christmas present to myself.

put on a Black Friday Sale that I bit the bullet. With the kits coming in at 20% off and my interest in the M&P platform reinvigorated, I couldn’t pass up the opportunity for an early Christmas present to myself.

When it comes to the Apex Tactical Kits, there are a couple of options to choose from. Since the Apex Tactical Forward Set Sear Kit is not Production Division legal, that one was out of the question. The Apex Tactical Competition Enhancement Kit

is not Production Division legal, that one was out of the question. The Apex Tactical Competition Enhancement Kit is a great option but it is not meant for Self Defense Applications due to the sub 3 pound trigger pull that it produces. This works against the idea of keeping the gun in a bedside table and most importantly, I’m not a fan of light triggers.

is a great option but it is not meant for Self Defense Applications due to the sub 3 pound trigger pull that it produces. This works against the idea of keeping the gun in a bedside table and most importantly, I’m not a fan of light triggers.

This left me with the Apex Tactical Duty Enhancement Kit that I’d had my eye on for some time. The DCAEK kit yields a consistent 5 pound trigger pull. Given the choice, I’d rather have the trigger closer to factory weight but roughly 1 pound lighter is close enough.

that I’d had my eye on for some time. The DCAEK kit yields a consistent 5 pound trigger pull. Given the choice, I’d rather have the trigger closer to factory weight but roughly 1 pound lighter is close enough.

There is one more addition I’m planning on making to the innards of my M&P, which is an Apex Tactical Reset Assist Mechanism (RAM). As the name implies, it will make the reset more pronounced. At roughly $23 for the RAM, it is just a matter of When The Balloon Goes Up

(RAM). As the name implies, it will make the reset more pronounced. At roughly $23 for the RAM, it is just a matter of When The Balloon Goes Up getting one in stock and I’ll place my order.

getting one in stock and I’ll place my order.

Grip Enhancement

When I made the switch from a Smith & Wesson M&P to a Glock 17 for USPSA, a couple of things happened. One of which was that I became sponsored by Custom Gun Finishes . To show off their services at matches, I was to have my Glock 17 DuraCoated. Originally the plan was to DuraCoat only the slide of my gun. Before the start of the season, that changed and plans were made to DuraCoat the frame as well.

. To show off their services at matches, I was to have my Glock 17 DuraCoated. Originally the plan was to DuraCoat only the slide of my gun. Before the start of the season, that changed and plans were made to DuraCoat the frame as well.

Looking back at it, I wish I would not have had the frame done. While I like the look of the gun, the feel is an issue. The DuraCoat top coat creates a smooth finish that can become slick, especially in the warmer months when the shooter begins to sweat.

While the grip of the M&P is not nearly as smooth as the Glock 17, it is considerably smoother than I would prefer. The cheapest and easiest way to increase friction would be to apply simple skate tape to key areas of the frame. Being very picky about certain things, I can already see the look of the hand-cut edges driving me crazy. I’m sure pre-cut options are available but I have yet to seek them out.

Stippling is also an option and based on what I’ve seen, it can be far more aggressive than grip or skate tape. My only issue with stippling is that it is permanent. It involves using a hot soldering iron to melt the polymer frame. If you don’t like the look or feel of it, too bad, because there is no undoing it.

Finished Product

When my Smith & Wesson M&P Production Division Gun Build (If you can even call it that) is complete, I should have a gun that is more pleasurable to shoot. I wish I could say for sure what I wanted out of this gun but I’m really not sure. Chances of me moving away from the Glock platform is slim. I’ve grown very fond of my Glock and it has been rock solid.

I can’t see selling the M&P when it is finished. I really do like it and there is an emotional attachment (it was my first range gun). Worse case scenario is that I wind up with a competition ready loaner gun for friends to borrow at matches.

Even though I’ve had a lot of trouble with the M&P, Smith & Wesson has stood behind their product without question. I respect that a great deal and it keeps Smith & Wesson in contention whenever I consider a new gun.

Ask The Readers

What are your thoughts on USPSA Production and IDPA Stock Service Pistol Divisions? Does what I’m doing go against the spirit of the division? If you consider yourself a purist, of sorts, where do you draw the line in making changes to guns for Production and SSP Divisions?

Recent Posts

From Group Ride Roasts to Real Life: My YouTube Channel Update

Well, my lovelies (I realize that sounds weird but at this point I need to lean into it), it's time for some real talk about where I've been and what's been happening behind the scenes at Walt in...

Reconnecting with friends, exploring scenic Pennsylvania back roads, and enjoying the simple pleasure of two wheels Getting the Band Back Together Today was a pretty special day in the...